Turbo Compressor

Introduction

A turbo compressor is a type of compressor that is driven by a turbine, which is powered by the exhaust gases of the engine. It is commonly used in internal combustion engines to increase the air density and, thus, the engine power output.

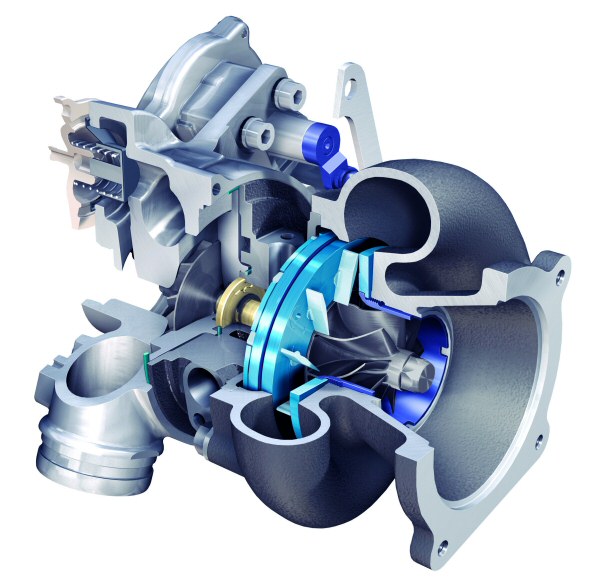

Parts of a Turbo Compressor

A turbo compressor consists of three main parts:

- Compressor Wheel: The compressor wheel is a rotating wheel with blades that compresses the incoming air.

- Turbine Wheel: The turbine wheel is connected to the compressor wheel through a shared shaft. It is driven by the exhaust gases of the engine, causing the compressor wheel to rotate and compress the incoming air.

- Housing: The housing is a casing that contains the compressor and turbine wheels. It also directs the incoming air to the compressor wheel and the exhaust gases to the turbine wheel.

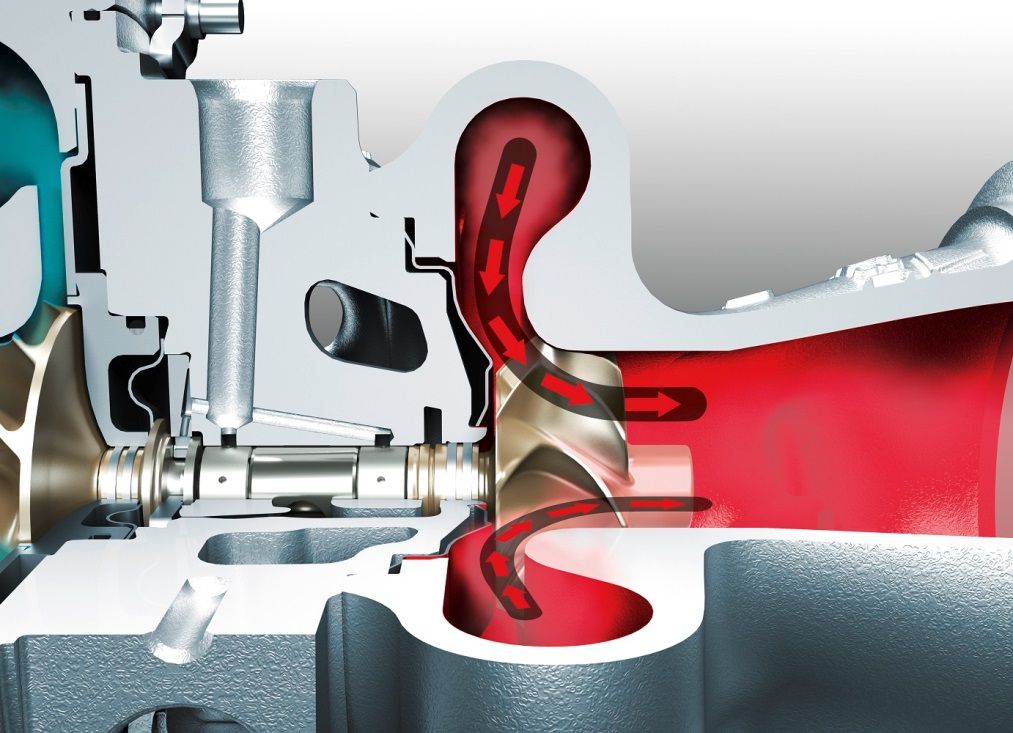

Working Principle

The working principle of a turbo compressor is as follows:

- The exhaust gases of the engine enter the turbine wheel through the turbine inlet.

- The turbine wheel rotates due to the force exerted by the exhaust gases, causing the compressor wheel to rotate through the shared shaft.

- The compressor wheel compresses the incoming air, increasing its density.

- The compressed air is then directed to the engine through the compressor outlet, where it is mixed with fuel and ignited to produce engine power.

Advantages and Disadvantages

Advantages of turbo compressors include:

- Increased engine power output

- Improved fuel efficiency

- Reduced exhaust emissions

- Compact size

Disadvantages of turbo compressors include:

- Complex design

- High initial cost

- Turbo lag (delay in engine response)

- Potential for overheating and damage due to excessive exhaust gas temperatures

Applications

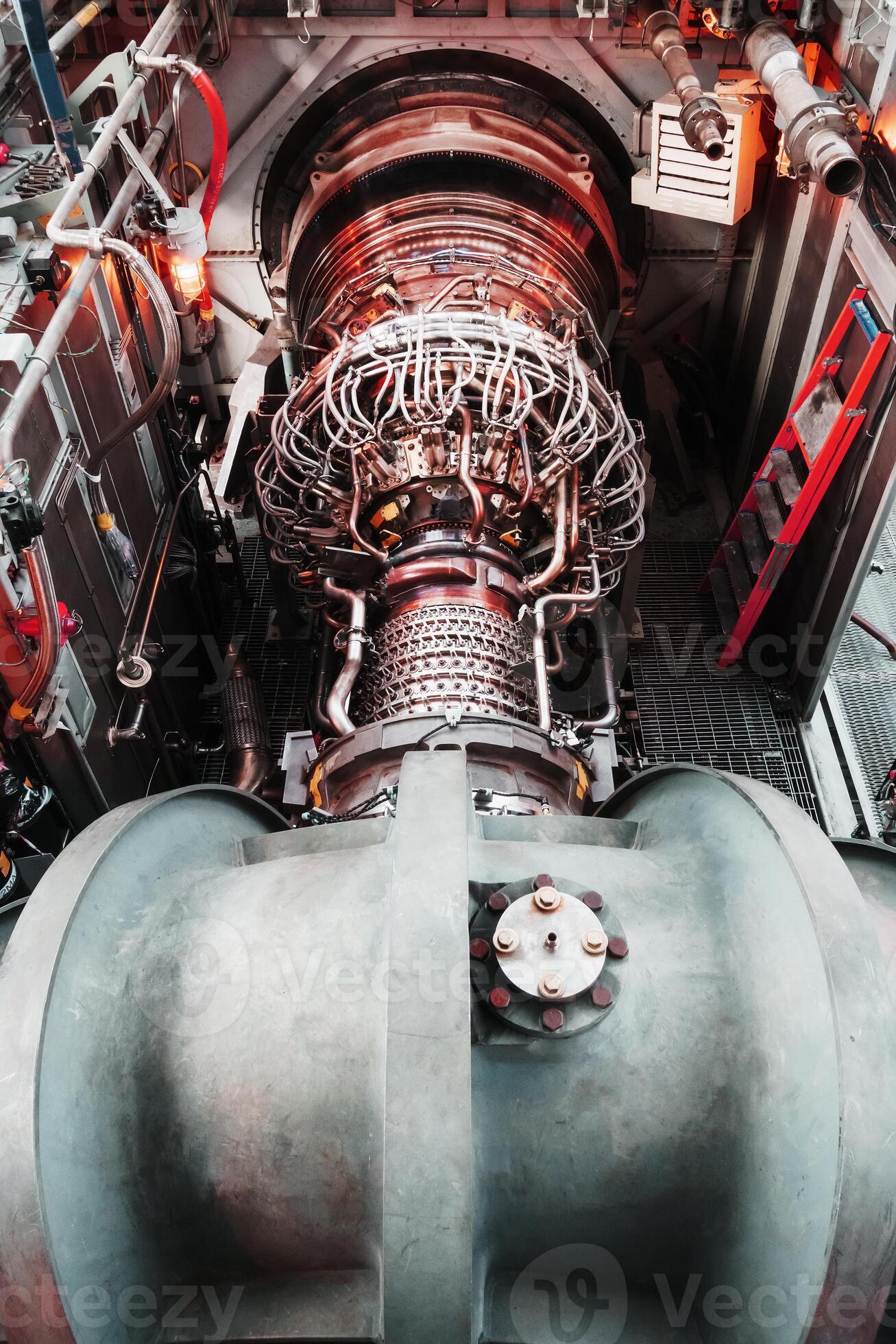

Turbo compressors are commonly used in:

- Automotive engines (cars, trucks, and buses)

- Gas turbines

- Industrial processes (e.g., chemical plants, oil refineries)

- Marine engines

- Locomotives

Conclusion

Turbo compressors are a type of compressor that are commonly used in internal combustion engines to increase the air density and, thus, the engine power output. They consist of a compressor wheel, a turbine wheel, and a housing. The turbine wheel is driven by the exhaust gases of the engine, causing the compressor wheel to rotate and compress the incoming air. Turbo compressors have several advantages, including increased engine power output, improved fuel efficiency, reduced exhaust emissions, and compact size. However, they also have some disadvantages, including complex design, high initial cost, turbo lag, and potential for overheating and damage due to excessive exhaust gas temperatures. Turbo compressors are commonly used in automotive engines, gas turbines, industrial processes, marine engines, and locomotives.